where passion

meets know-how

Since its start up in 1946 the company

has been located in Leverkusen, close to

Cologne - western part of Germany. This

area is noted for its excellent

infrastructure and highly skilled

employees.

Today there is a CNC component supply

facility separate from the parent firm.

the art

of x-ray

We produce every individual

component ourselves. That way

we keep a continuous control of

the results. Additional to this it

allows us to quickly transform

new tube models or variants of

existing models.

Our long history of experience

in this area, makes it possible for

us to implement complex

components for single or series

tubes.

less is more

To construct high-performance and reliable

X-ray tubes we strive to keep the material

used to a minimum. With our unique

technology a complete vacuum can be

created, without the need to adopt the

usual “Getter“ (chemical reactive material):

the result is an unusually long service life.

Additional to the numerous quality tests

during production, we carry out repeated

functional tests at high-voltage for each

individual X-ray tube. In spite of all the

experience, the manufacture of an X-ray

tube remains a complex and high-risk

process. That is why the substantial effort

involved for all the fail-safe testing is an

investment well made.

Well reputed as a reliable and loyal

source we are supplying to

worldwide market leaders with high

volume applications like:

•

Non Destructive Testing (weld or

aircraft inspection and many others)

•

Security applications

(baggage inspection, letter bomb

detection, etc.)

•

Gauging (metal thickness

gauging in the steel industry)

•

Medical applications (Radiography,

CT,

densitometry)

•

Food industry (contaminants

detection)

the family business

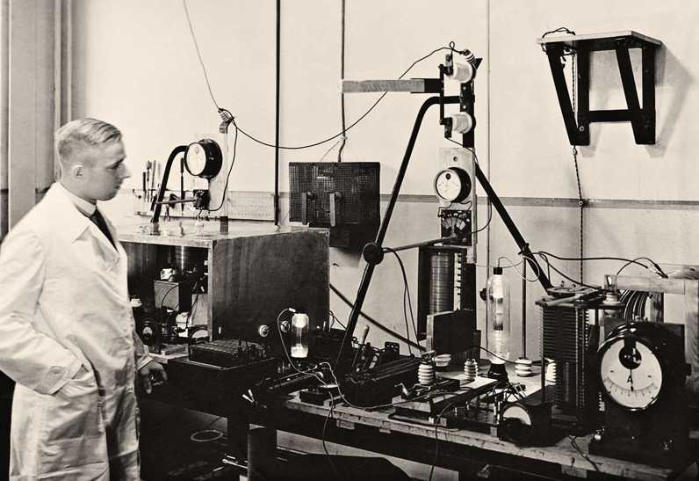

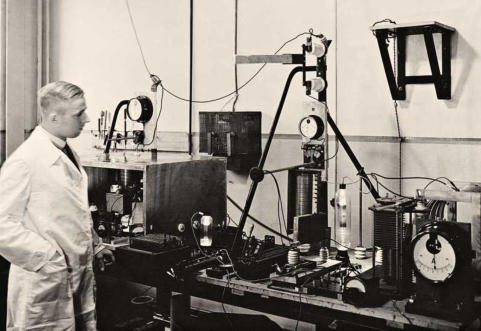

1930s. Dr. Franz Lohmann in his laboratory.

Lohmann X-Ray GmbH has been founded in postwar (West-) Germany as a

private enterprise by Dr. Franz Lohmann in 1946 to produce X-Ray tubes for

industrial applications.

Franz Lohmann

Since the 1930s Dr. Franz Lohmann

has been investigating vacuum

technology. On the 1st January 1946,

out of the ruins of the Second World

War, he built his small X-ray tube

factory and in so doing literally laid the

foundations for the process that isstill

being used today. In 1956 the plant

was moved within Leverkusen to its

current location. In the first phase of

production the company specialized in

tubes for medical treatment, rectifier

tubes and tubes for NDT (non-

destructive testing) that were at first

small commissions for customers in

Germany and around Europe.

Hermann Lohmann

In 1968 the company was taken over

by son, Franz Lohmann passing it on to

the second generation. Under his

command the NDT side of the

business was upgraded, an own line of

X-ray equipment was developed and

distribution was expanded into the

USA and many other countries. In the

early 1980s amongst other things the

company became leader in the market

for baggage inspection machines at

airports, as well for specialist medical

machines. The quantity of X-ray tubes

produced increased steadily resulting

in the building of the company’s first

extended annex.

Lothar Lohmann

1990

saw

Lothar

Lohmann

as

third

generation

family

member

commence

his

work

for

the

company,

which

he

eventually

took

over

from

his

father

in

2001.

Optimized

processes

allowed

the

production

number

of

tubes

to

be

increased

with

some

additional

characteristic

improvements

on

them.

Additionally

the

market

was

opened

into

Asia

and

new

applications

were

introduced,

e.g.

in

the

medicine

sector

and

for

food

inspection.

At

present

a

newly

built company annex houses the glass technique department. The component themselves are manufactured at a

different location.

where passion

meets know-how

Since its start up in 1946 the

company has been located in

Leverkusen, close to Cologne -

western part of Germany. This

area is noted for its excellent

infrastructure and highly skilled

employees.

Today there is a CNC

component supply facility

separate from the parent firm.

the art

of x-ray

We produce every individual

component ourselves. That way

we keep a continuous control of

the results. Additional to this it

allows us to quickly transform

new tube models or variants of

existing models.

Our long history of experience

in this area, makes it possible for

us to implement complex

components for single or series

tubes.

less is more

To construct high-

performance and reliable

X-ray tubes we strive to

keep the material used to

a minimum. With our

unique technology a

complete vacuum can be

created, without the need

to adopt the usual

“Getter“ (chemical

reactive material): the

result is an unusually long

service life.

Well reputed as a reliable and loyal

source we are supplying to worldwide

market leaders with high volume

applications like:

•

Non Destructive Testing (weld or

aircraft inspection and many others)

•

Security applications

(baggage inspection, letter bomb

detection, etc.)

•

Gauging (metal thickness

gauging in the steel industry)

•

Medical applications (Radiography,

CT, densitometry)

•

Food industry (contaminants

detection)

the family business

1930s. Dr. Franz Lohmann in his laboratory.

Lohmann X-Ray GmbH has been founded in postwar (West-) Germany

as a private enterprise by Dr. Franz Lohmann in 1946 to produce X-

Ray tubes for industrial applications.

Franz Lohmann

Since the 1930s Dr. Franz Lohmann

has been investigating vacuum

technology. On the 1st January

1946, out of the ruins of the Second

World War, he built his small X-ray

tube factory and in so doing literally

laid the foundations for the process

that isstill being used today. In 1956

the plant was moved within

Leverkusen to its current location. In

the first phase of production the

company specialized in tubes for

medical treatment, rectifier tubes

and tubes for NDT (non-destructive

testing) that were at first small

commissions for customers in

Germany and around Europe.

Hermann Lohmann

In 1968 the company was taken over

by son, Franz Lohmann passing it on to

the second generation. Under his

command the NDT side of the business

was upgraded, an own line of X-ray

equipment was developed and

distribution was expanded into the

USA and many other countries. In the

early 1980s amongst other things the

company became leader in the market

for baggage inspection machines at

airports, as well for specialist medical

machines. The quantity of X-ray tubes

produced increased steadily resulting

in the building of the company’s first

extended annex.

Lothar Lohmann

1990 saw Lothar Lohmann as third

generation family member commence

his work for the company, which he

eventually took over from his father in

2001. Optimized processes allowed

the production number of tubes to be

increased with some additional

characteristic improvements on them.

Additionally the market was opened

into Asia and new applications were

introduced, e.g. in the medicine sector

and for food inspection. At present a

newly built company annex houses the

glass technique department. The

component themselves are

manufactured at a different location.

Additional to the numerous quality tests during production, we

carry out repeated functional tests at high-voltage for each

individual X-ray tube. In spite of all the experience, the

manufacture of an X-ray tube remains a complex and high-risk

process. That is why the substantial effort involved for all the

fail-safe testing is an investment well made.

PRODUCTS

COMPANY

LOHMANN

PRODUCTS

COMPANY

LOHMANN